Clays for Reduction Firing With Gas and Wood

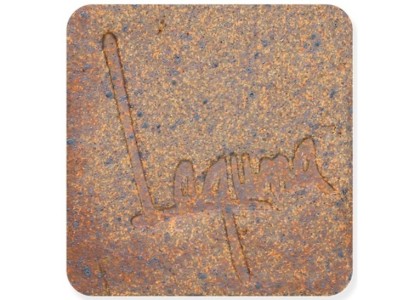

Reduction firing in gas or wood kilns offers artists and potters access to a unique palette of surface effects, depth and character that electric oxidation firing struggles to replicate. Selecting the right clay body for reduction is essential for achieving the right strength, colour response and surface richness. Reduction-fired ceramics offer timeless appeal and tactile surfaces, achieved through altering the kiln atmosphere by limiting oxygen and therefore forcing metallic oxides in glazes and clay bodies to shift chemically. This process is a key part of unlocking effects like iron speckling, rich greens and earthy stoneware tones.

Clay Bodies Suitable for Reduction Firing

To work well in reduction firing, clay bodies need to be formulated to withstand thermal stress and retain their form in a reduction atmosphere. Clays high in iron oxide, ball clay or fireclay, as well as those with balanced grog content, are especially suited to reduction firing and react beautifully.

Our clays for gas kiln and wood firing are selected for their performance in cone 6 to cone 10 reduction firings, at approximately 1220°C to 1300°C. Whether you have been handbuilding, throwing or modelling your clay, selecting the right clay ensures there is excellent resistance to cracking, durability, excellent colour response and compatibility with a range of types of glaze.

Reduction Fired Clays for Creative Exploration

The surface effects made possible through reduction firing are exciting, but choosing the right clay is important for ensuring success in the kiln. It's important to consider whether you're looking for a smooth body for glaze work or something textured for sculpting or ceramics. You'll find a clay ideal for reduction firing at Potclays.

Reduction firing produces distinctive textures and colourful displays. Understanding the atmosphere of your kiln and how to control the reduction firing process can influence the end result drastically, so it's important to test your clay and glazes by using a tile first. Surface effects can span from earthy reds to glassy brilliance, perfect for the production of one-off art pieces.

Why Choose Potclays?

At Potclays, we're proud to be a one-stop shop for all things pottery and ceramics, providing tools and accessories, clays and even kilns to meet the needs of all skill levels. With over 90 years of experience and expertise, we can help you select the right glazes and more to meet your creative goals.

Have a question or need help understanding the firing process? We're happy to help, no matter the problem. Get in touch with us today.