Plastic Clays

Choosing the right clay is essential to achieving consistency, form and finishing quality, whether you're hand-throwing, slip casting, sculpting or even producing ceramic bodies at scale. We offer a comprehensive selection of clays designed to meet the needs of hobbyists, artists and production ceramicists, all sourced from trusted suppliers and processed with meticulous care. Each clay body is selected for its plasticity, firing range and compatibility with glazes. Explore our range today.

Plastic Clays for Versatile Forming and Workability

Our plastic clays are ideal for both beginners and experienced potters alike. With high moisture content and excellent plasticity, these clays are easy to shape and throw.

Many contain kaolinite, mica and finely divided mineral particles that assist in retaining form during the drying process, and are often used in the base of some clay recipes. These clays are known for their strength and handling properties.

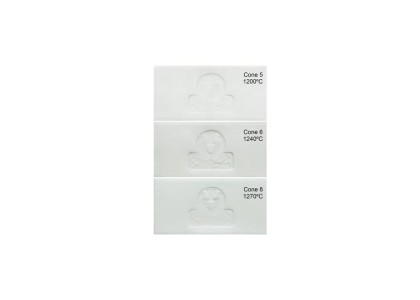

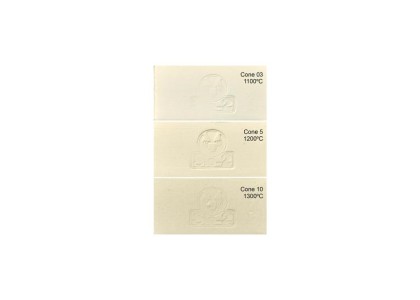

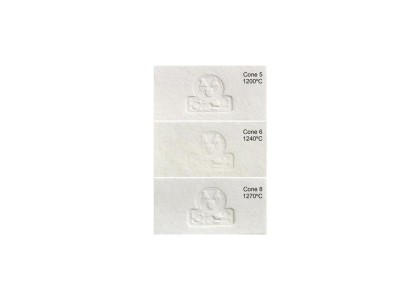

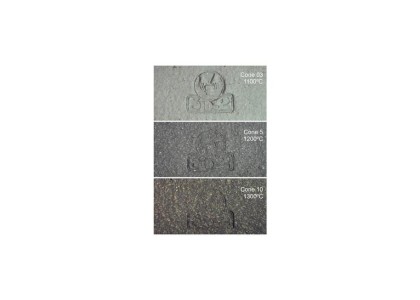

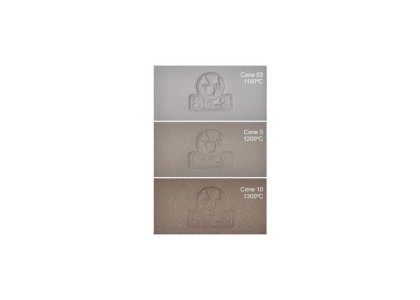

Different options have different firing ranges, different fired colours, and are suitable for different techniques.

Grogged Clays and Ball Clays

Our plastic clay range includes clays that are grogged, containing crushed, pre-fired ceramic for added strength and resistance to cracking, and reduced shrinkage. These characteristics make these clay bodies best for sculptors or those building large forms by hand.

Ball clays are also popular and highly valued for their ability to improve the working properties of other bodies. They are ideal for adjusting a clay recipe, controlling fired colour or tailoring clay to specific production processes.

Manufacturing Methods of Prepared Clay Bodies

Bodies marked with a 'P' are finished by our Panmilling technique. This production method gives excellent, reliable control of grog and water contents but is inherently more open to occasional larger or extraneous particles arising in the ingredients or during processing. It generally produces better moisture control in grogged bodies.

Bodies marked with an 'S' are Sliphoused bodies. These are prepared in very large batches in slip form which is finely sieved prior to or after grog addition. The purified slip is then pumped into presses for dewatering prior to pugging. Sliphousing gives greater product uniformity and virtually guarantees freedom from contamination, but it is more difficult to control grog contents due to settling from suspension and moisture content. It is the best technique for smooth-textured bodies.

Bodies marked with a 'PB' are produced by a Plastic Blending process, which yields bodies offering the high purity and cost effectiveness of a sliphoused product together with the ultra-tight control over grog additions offered by the panmilling process.

Why Choose Potclays?

We're trusted by all types of potters - from hobbyists to those involved in production. Combining industry expertise with a passion for all things crafts, our clay products are all tested for quality, consistency and workability. We're proud to offer a range of high quality products available to meet the wide needs of ceramicists. Find powder glaze, kilns and more in our range.

Our clays are also available in a range of colours to suit your requirements.

Need assistance or advice? Get in touch with us today. We're happy to help.